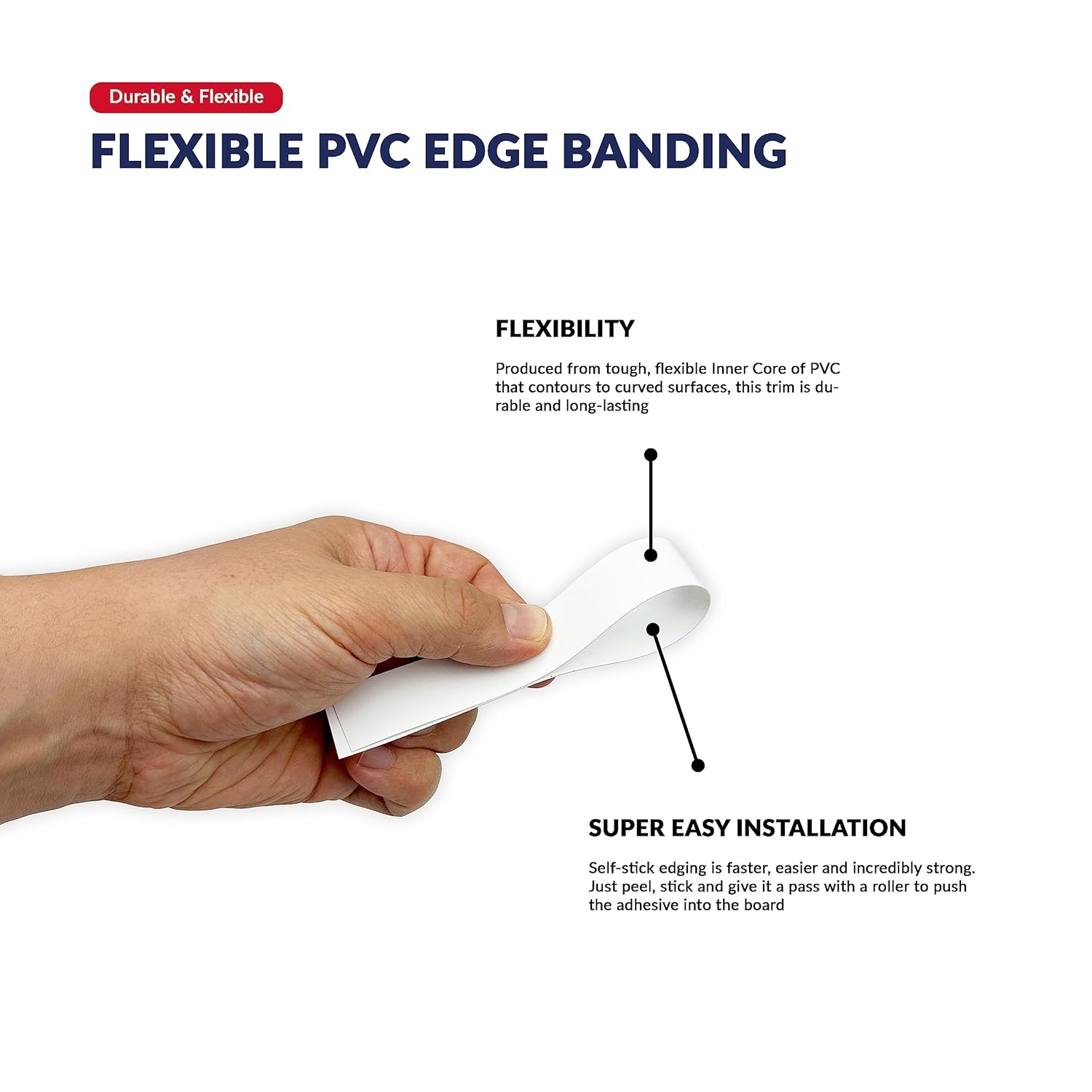

- HIGH QUALITY FLEXIBLE PVC TRIM – This trim is durable and long-lasting. Made to cover the edges of furniture, shelves, machines and general DIY projects, this edge trim can be applied with a roller or a wood block for a perfect bond to any type of surface

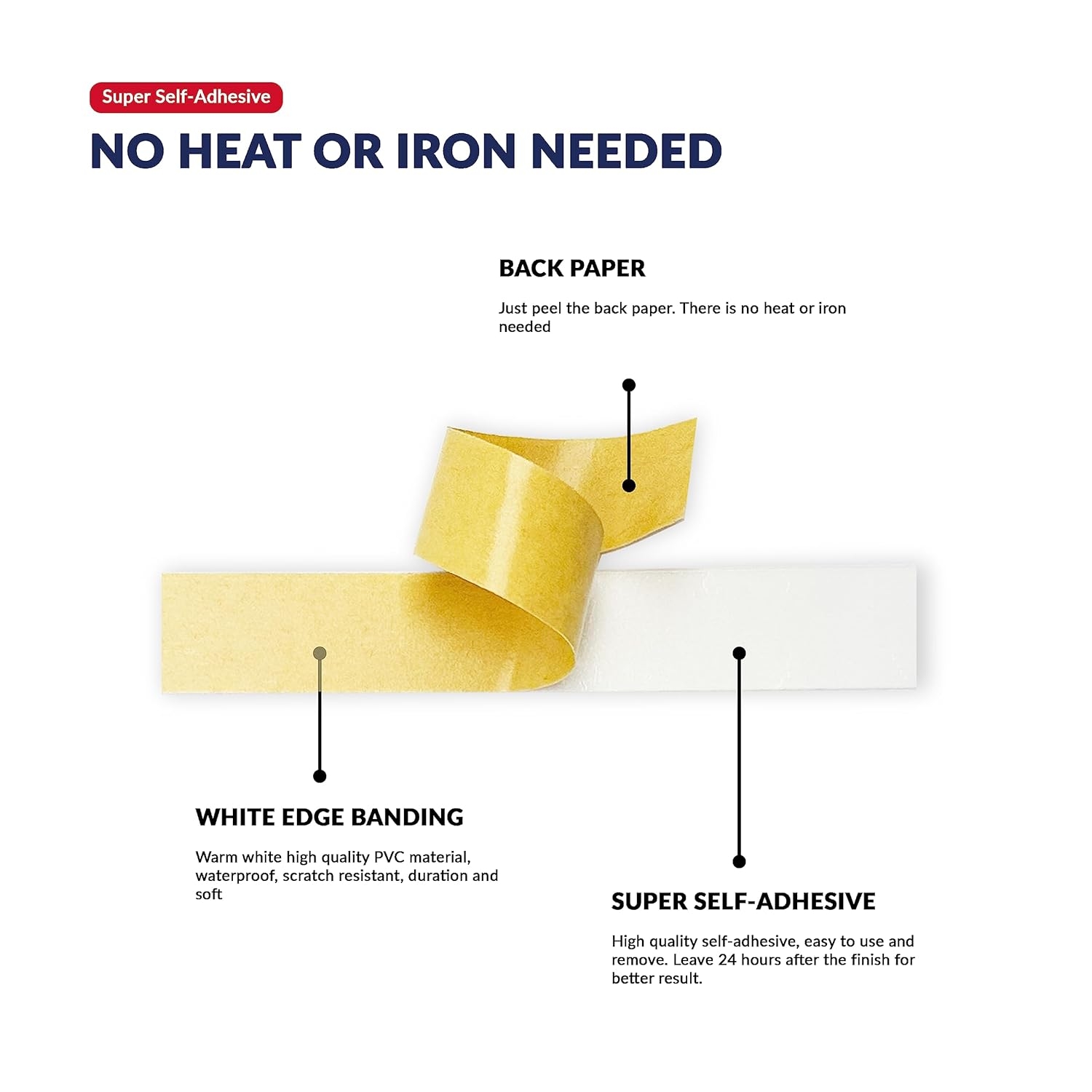

- PEEL AND STICK WHITE PVC EDGE BANDING – Self-stick edging is easier than standard pre-glued edge bandings. Offers very short application time and has an incredibly strong adhesive. Just peel, stick and give it a pass with a roller to push the adhesive into the mdf, plywood or particleboard and all done. This roll of premium quality PVC edge banding Peel & Stick can be cut to your required size and used to trip multiple types of DIY projects

- VERSATILE FLEXIBLE EDGE TRIM – our customers use this premium edge banding for a wide range of uses including furniture, kitchens, countertop edging, decorative edging, and shelfs – ideal for high traffic area’s where edges a modern high end and durable finish is required product

- SIZING – The 1 1/2 inch x 25 feet trim can be cut to size as required and trim with a utility knife, a strong scissors, or an edge trimmer capable of cutting 0.40 mm edge banding

- EASY APPLICATION PVC EDGING – thanks to the strong durability of this PVC edge banding, it can be easily applied to your surface using a roller or a wood block for a fast and durable bond in just a few minutes. There is no heat or ıron required

Product Description

|

|

|

|

|

|---|---|---|---|

Premium QualitySelf-stick edging is easier than standard pre-glued edge bandings. Offers very short application time and has an incredibly strong adhesive. Just peel, stick and give it a pass with a roller to push the adhesive into the mdf, plywood or particleboard and all done. |

Widely UseThis trim is durable and long-lasting. Made to cover the edges of furniture, shelves, machines and general DIY projects, this edge trim can be applied with a roller or a wood block for a perfect bond to any type of surface. |

No Heat or Iron RequiredThanks to the strong durability of this PVC edge banding, it can be easily applied to your surface using a roller or a wood block for a fast and durable bond in just a few minutes. There is no heat or iron required |

Strong Self AdhesiveOur customers use this premium edge banding for a wide range of uses including furniture, kitchens, countertop edging, decorative edging, and shelfs – ideal for high traffic area’s where edges a modern high end and durable finish is required product |

|

|

|

|

|

|---|

PEEL & STICK WHITE PVC EDGE BANDING

PREMIUM A+ QUALITY EDGE BANDING

Self-stick edging is easier than standard pre-glued edge bandings. Offers very short application time and has an incredibly strong adhesive. Just peel, stick and give it a pass with a roller to push the adhesive into the mdf, plywood or particleboard and all done. This roll of premium quality PVC edge banding Peel & Stick can be cut to your required size and used to trip multiple types of DIY projects

SIZING

The trim can be cut to size as required and trim with a utility knife, a strong scissors, or an edge trimmer capable of cutting 0.40 mm edge banding

Benefits of the Product

- A+ Quality

- Peel & Stick

- Perfect bonding

- Short application time

- Durable and long-lasting

- No heat or iron required

APPLICATION

|

|

|

|

|

|---|---|---|---|

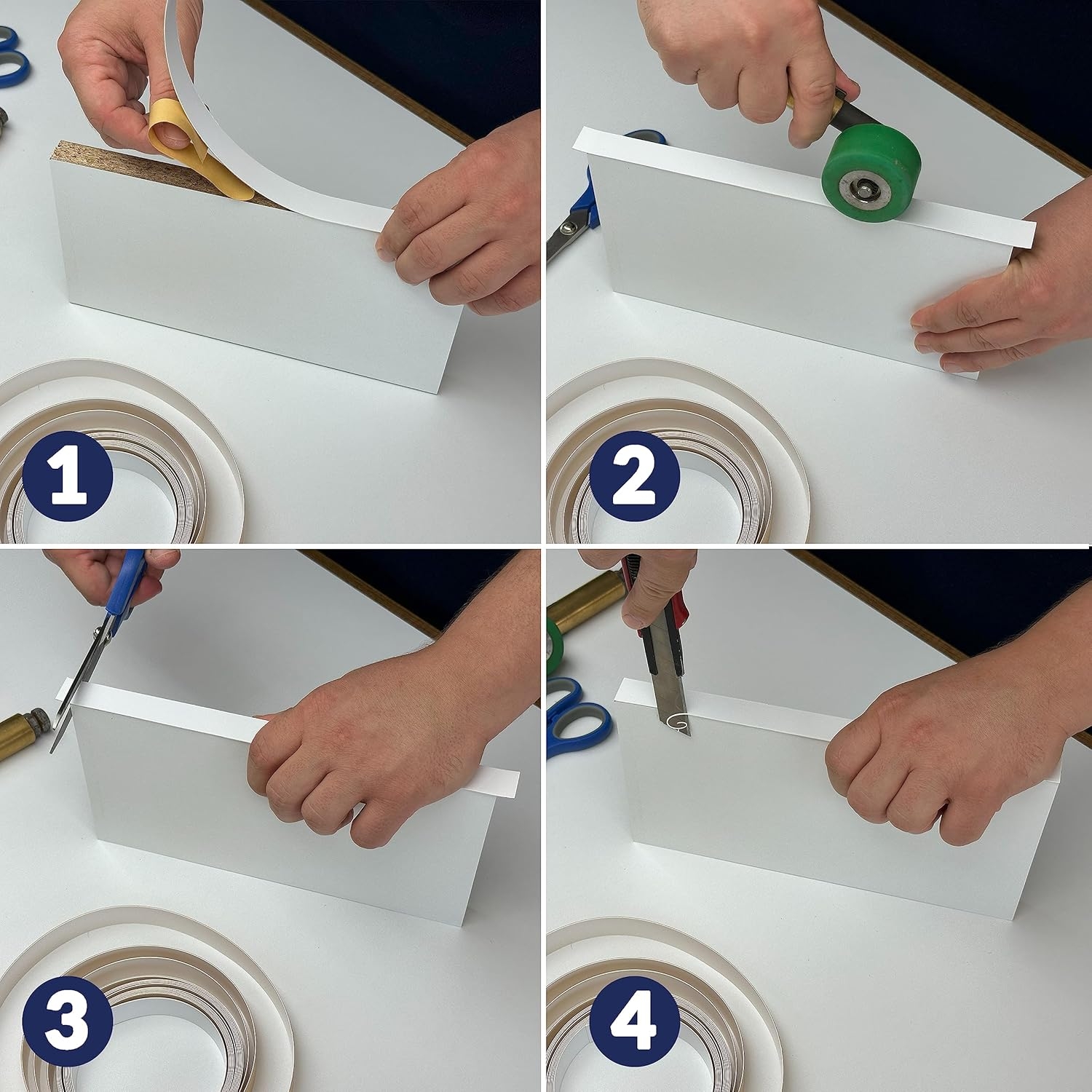

STEP 1Peel away the back paper and stick the tape to the edge |

STEP 2Press down with a roller through the edge |

STEP 3Cut the excess edge banding with a scissors |

STEP 4Trim off the excess edge banding with a utility knife |

Product Description

UNMAR White PVC Peel and Stick Edge Banding

From the Manufacturer Unmar LLC

Peel and stick PVC edge banding offers several advantages in various applications, particularly in woodworking, cabinetry, and furniture manufacturing.

Here are some of the key advantages:

- Easy Application – One of the primary benefits of peel-and-stick PVC edge banding is its simplicity and ease of application. It eliminates the need for specialized tools or adhesives, making it accessible to DIY enthusiasts and professionals alike. You can simply peel off the backing and adhere it to the edge of your material.

- Time Efficiency – Traditional edge banding methods often involve gluing, clamping, and waiting for adhesives to dry. Peel-and-stick edge banding saves time as there’s no drying time required. This can significantly speed up production processes.

- Cost-Effective – Since there’s no need for additional adhesives or specialized equipment, peel-and-stick PVC edge banding can be cost-effective when compared to traditional edge banding methods.

- Clean and Neat Appearance – When applied correctly, PVC edge banding provides a clean and polished appearance to the edges of materials like plywood or particleboard. It covers any exposed edges, preventing splinters and enhancing the overall aesthetics of the finished product.

- Durability – PVC is known for its durability and resistance to moisture, chemicals, and abrasion. When used as edge banding, it helps protect the edges of your furniture or cabinetry from wear and tear, making them more long-lasting.

- Flexibility – PVC edge banding is flexible and can be easily applied to curved or contoured edges, providing a smooth and consistent finish even on non-linear surfaces.

- Repairability – If the edge banding gets damaged or starts to peel over time, it can be relatively easy to replace or repair by simply removing the old banding and applying a new one.

While peel and stick PVC edge banding offers many advantages, it’s essential to ensure proper application to achieve the best results. Make sure to clean and prepare the edge of the material before applying the banding, and use a roller or edge banding trimmer to ensure proper adhesion and a clean finish.